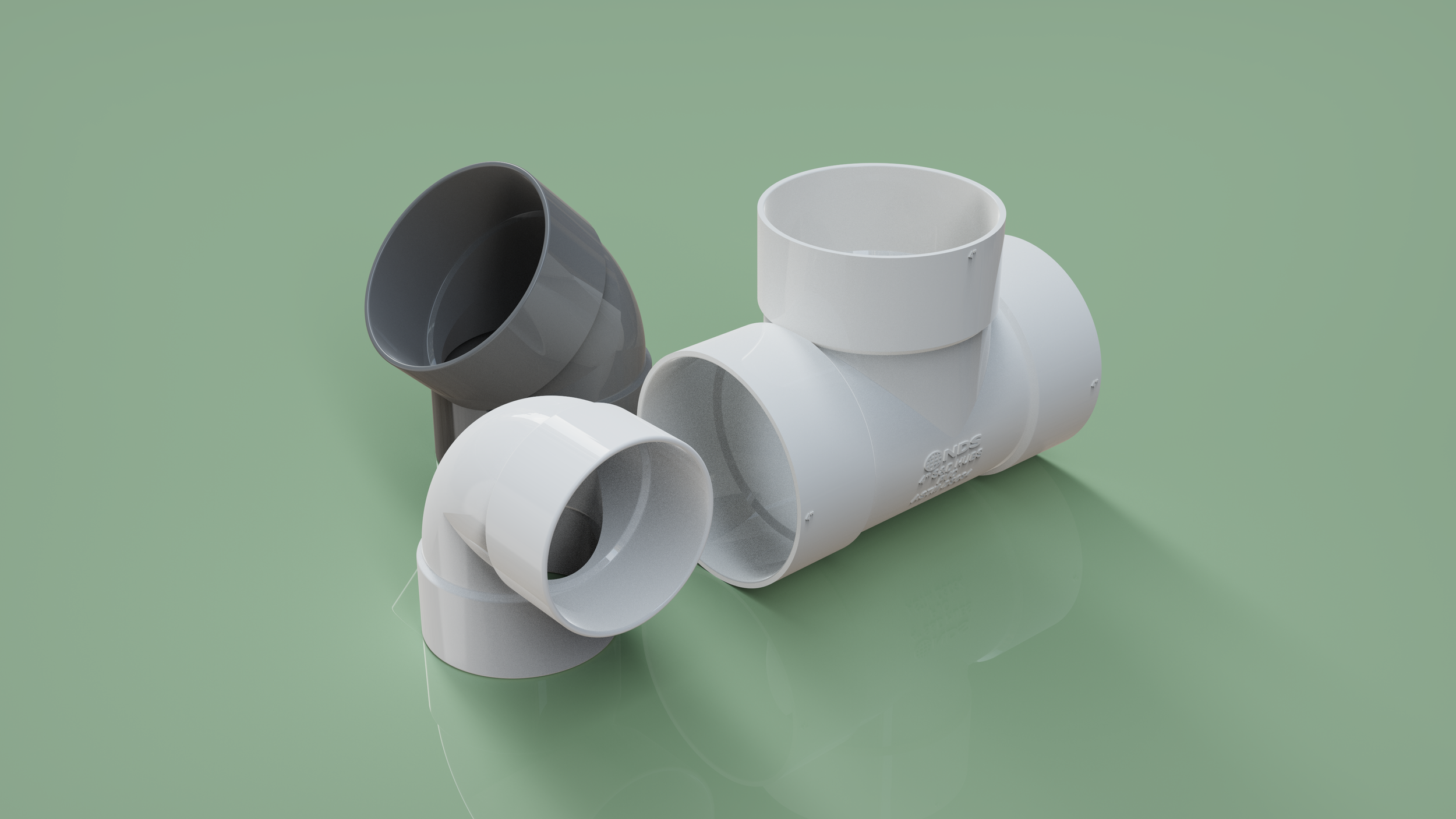

PVC Fittings

Wong, Bryce. 2021.

Designed and manufactured in California.

Over the course of my career, I have designed and developed more than 20 PVC pipe fittings, each engineered to comply with the relevant ASTM standards governing dimensional tolerances, pressure ratings, material properties, and performance requirements. My work spans couplings, elbows, tees, adapters, and specialty transition fittings used in drainage and pressure applications.

All components were fully modeled in SolidWorks, where I created complete parametric geometries, drafted manufacturing-ready drawings, and incorporated design-for-manufacture considerations such as draft angles, wall transitions, knit-line placement, and moldability constraints. I routinely conducted tolerance stack-ups, interference analyses, and structural evaluations to ensure proper sealing, joint integrity, and long-term durability under expected field loads.

During development, I also collaborated with materials engineers to verify resin selection, ensured chemical compatibility and environmental resistance, and supported pressure testing protocols to validate compliance with ASTM performance requirements.

Across the full product lifecycle, I led program planning, technical design reviews, tooling feasibility assessments, first-article inspections, and cross-functional coordination with engineering, tooling, manufacturing, quality, supply chain, and marketing teams. This end-to-end involvement ensured smooth execution, robust manufacturability, and accelerated time-to-market for each new fitting.

These efforts have resulted in a reliable portfolio of ASTM-compliant fittings that deliver consistent performance and have been well received by both distributors and end users.